Assinck offers a full range of precision-engineered conveyor pulleys built to perform under the toughest conditions. Whether you need standard or heavy-duty solutions, our Drum Pulleys and Wing Pulleys are designed with strength, efficiency, and longevity in mind – helping reduce downtime and maintenance on site

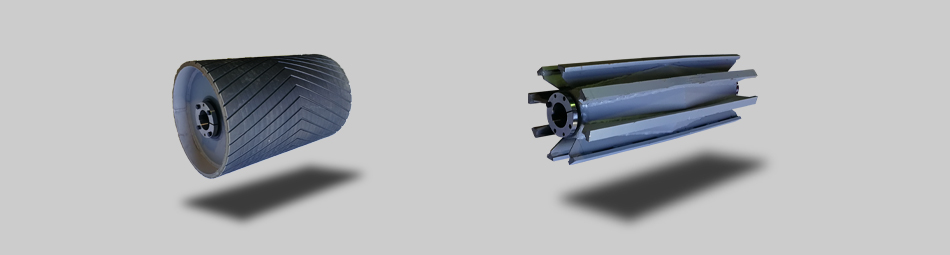

Drum Pulleys

Our Drum Pulleys (12″ to 60″ OD, 12″ to 63″ face width) are cold-formed using custom-designed crowning rolls, increasing rim strength and reducing radial deformation. With a full-depth submerged arc weld and uniform crowning, these pulleys offer consistent belt tracking and torque performance.

Key Features:

- Crowned face built directly into plate roll

- Sealed full-depth welds on both sides

- Tapered compression hubs available

- Engineered pulleys for specialty applications

- Optional vulcanized rubber lagging (smooth or grooved patterns)

Whether you need extra traction or abrasion resistance, our lagged drum pulleys are tailored for durability – and built to last.

Wing Pulleys

Assinck’s Wing Pulleys provide automatic self-cleaning and are designed to minimize belt wear and misalignment. With a double cone construction, full-length pipe welds, and gusset-reinforced wings, these pulleys are built for demanding applications.

Available Sizes:

10″ to 36″ OD | 12″ to 66″ Face Width

AR400 Wing Pulleys:

We’ve introduced a new generation of heavy-duty Wing Pulleys featuring AR400 plated tops/bars. These pulleys offer up to 4X the life of traditional designs – reducing rebuilds and keeping your operations running cost-effectively.

Benefits:

- Thicker wings and tubular design for added integrity

- AR400 bar tops for maximum wear resistance

- In-stock standard sizes and custom builds available

- Supplied complete with hubs and bushings

- Emergency orders welcomed

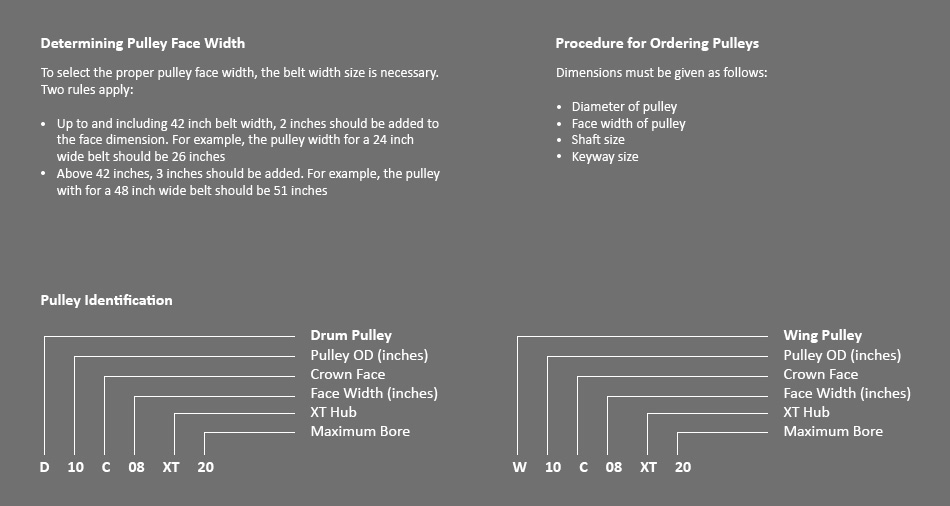

Information Guide