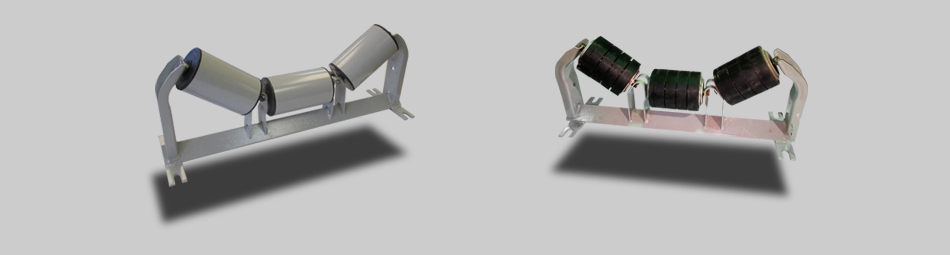

Assinck’s idlers are precision-engineered to deliver durability, smooth performance, and long service life in the most demanding environments. Available in 4″, 5″, and 6″ diameters, our troughing idlers and return rollers are manufactured using heavy No.10-gauge seamless tubing, ensuring robust construction and consistent performance across all material handling applications.

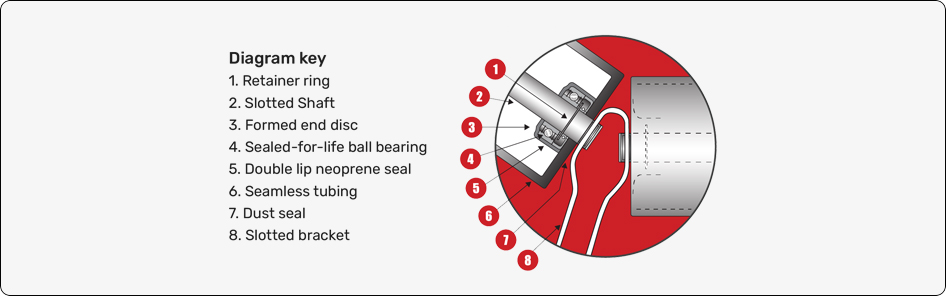

Each roller is built with a Sealed-for-Life ball bearing, pressed onto a specially machined shaft and secured with a retainer ring. The assembly is further protected by a double lip neoprene seal and dust flanges to prevent contaminants from reaching the bearing area – significantly extending product lifespan.

Our frames feature die-formed, channel-type end brackets supported by heavy-duty angled bases. The rollers meet CEMA Class C standards, suitable for medium-duty applications, and are designed to support either 20° or 35° troughing angles, depending on your conveying requirements.

Key Features:

- Double slotted shaft design prevents shaft rotation within the bracket

- Optional rubber lagging for return rollers

- All components field-tested for maximum performance

- Carrier and return rollers include impact options for high-load zones

- Rollers and frames are also available separately

Longer life. Less maintenance. Built to perform.

Idler Diagram