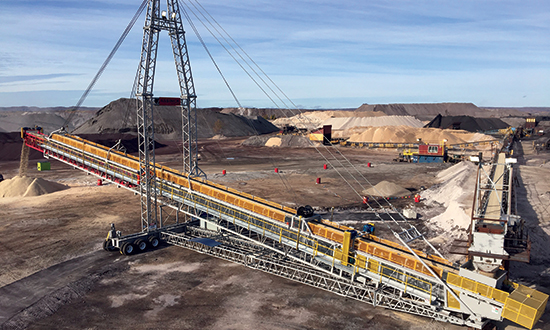

Algoma Steel – 3000 TPH Ship Loading Telescopic Stacker

Client: Algoma Steel

Location: Ontario, Canada

Industry: Steel Production & Bulk Material Handling

Project Type: Custom Design & Build Ship Loading System

Project Duration: 6 months (from design inception to commissioning)

Stacker Throughput: 3000 TPH

Project Overview

Assinck Limited was engaged by Algoma Steel to design and build a custom ship loading telescopic stacker with a capacity of 3000 TPH. The primary objective was to integrate the new system seamlessly into the client’s existing infrastructure while ensuring operational efficiency and minimizing downtime. The Shiploader was designed to optimize loading processes and reduce demurrage costs, which are substantial fees incurred for delays in loading operations.

This project demanded a highly customized approach to ensure that Algoma Steel could maintain a competitive edge in material handling while maximizing operational uptime.

The Challenge

- Infrastructure Compatibility: The new telescopic ship loader had to be designed to fit within the existing footprint and runway at Algoma Steel’s facility.

- Minimizing Downtime: Building redundancy into the machine was critical to ensure that the system remained fully operational during ship-loading campaigns, effectively reducing the risk of costly demurrage charges.

- Enhanced Communication Systems: The loading process required a sophisticated communication network for personnel across various operational zones, including ground operators, site supervisors in the “bull pit,” and loader operators feeding materials into the system.

The Solution

To meet Algoma Steel’s needs, Assinck Limited designed and built a highly efficient ship loading telescopic stacker capable of handling up to 3000 TPH. This custom-built system was engineered to align with the existing infrastructure while incorporating advanced redundancy measures to ensure uninterrupted operations.

Key components of the solution included:

- Telescopic Ship Loader: Engineered for seamless integration into Algoma Steel’s existing runway and loading infrastructure.

- Redundancy Mechanisms: Designed to eliminate downtime, ensuring continuous loading operations and mitigating demurrage risks.

- Advanced Communication Network: Implemented an innovative communication system that featured:

- Three strategically placed 18” HMI (touchscreen displays) for real-time monitoring and control.

- Wireless remote controls for both ground operators and wheel loader personnel to enhance coordination and responsiveness.

Customization and Innovation

As with many of Assinck’s projects, customization was key. This ship loading system was uniquely designed from inception to provide maximum flexibility in handling different material gradations, ensuring Algoma Steel could readily adapt to evolving industry demands.

Innovative Features:

- Blending Gates with Electric Solenoid Valves: Operators can easily adjust material flow and composition with the push of a button, allowing for on-the-fly customization.

- Highly Automated Controls: The ship loader is equipped with state-of-the-art automation, enabling precise, real-time adjustments to optimize throughput and quality control.

Project Timeline

The entire project, from the initial design and engineering phases to commissioning, was successfully completed within six months.

Results

The results were highly satisfactory, with the ship loader delivering on all key performance metrics:

- 3000 TPH Throughput: Meeting and exceeding operational requirements.

- Seamless Infrastructure Integration: Successfully incorporated within the existing footprint and loading area.

- Customization Capabilities: The system allows for virtually any gradation of material, ensuring Algoma Steel remains competitive.

- Enhanced Efficiency: The plant operates with only two personnel, significantly reducing labor costs while maintaining full operational capacity.

Operational Impact

The new ship loading stacker has dramatically improved Algoma Steel’s operational efficiency by:

- Reducing potential demurrage costs by ensuring smooth and continuous loading operations.

- Enhancing safety and communication through advanced monitoring and control systems.

- Providing highly customizable material output, enabling the company to meet diverse customer specifications.

Innovation and Futureproofing

The introduction of blending gates with electric solenoid valves marks a significant step in automation and flexibility. Operators can now make real-time adjustments with ease, improving efficiency and responsiveness to operational changes. This innovation positions Algoma Steel for long-term adaptability, ensuring sustained operational excellence in the bulk material handling industry.

Outcome

Since commissioning, the new ship loading telescopic stacker has been fully operational, consistently hitting production targets. Algoma Steel now benefits from a cost-effective, high-performance loading system that reduces downtime, optimizes material handling, and ensures long-term sustainability in the industry.